Based mainly on observed sea conditions (on land it is categorized. Reading the “User manual” is highly.

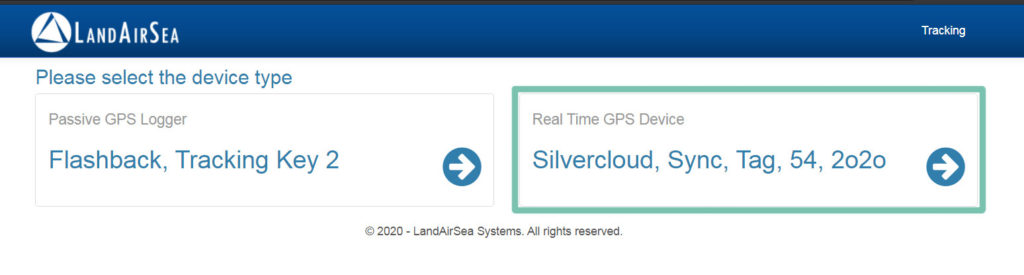

- Land Air Sea 54 User Manual Download

- Land Air Sea 54 User Manual Pdf

- Land Air Sea 54 User Manual 2

- Land Air Sea 54 User Manual 2017

- Air Force units will validate and incorporate appropriate procedures in accordance with applicable governing directives. Distribution is in accordance with AFI 33-360. User Information a. The TRADOC-MCCDC-NWDC-Air Force Doctrine Center (AFDC) Air Land Sea Application Center (ALSA) developed this publication with the joint.

- Operator's Manual. Find, View or Buy Manuals and Maintenance & Service Intervals. Find and View Operator’s Manual. Your Operator’s Manual information that includes key information. To find and view information, complete the following steps: 1. Enter the Decal Model Number or up to three keywords and select 'Search'.

Force Provider (FP)

A 'city in a box,' Force Provider (FP) is a combat multiplier being used as a forward deployed system that increases combat capabilities by providing superior living conditions beyond that ever experienced by soldiers.

Unlike the Air Force, the Army planned to fight from tents in Operation Desert Shield. If it became necessary to build a base camp, the Army would build expedient structures according to the Army Facilities Component System, TM 5-300 series. These technical manuals laid out the base camp facilities and provided detailed construction plans for individual structures. The Army had not placed the same emphasis on facilities as the Air Force. As a result, it did not have enough tents to meet its needs. Some soldiers slept in their vehicles. It deployed highly complex and costly equipment without providing adequate protection from the harsh climate. The need for facilities quickly became apparent. The Aviation Support Command, for example, hurriedly procured clamshell buildings-prefabricated, aluminum framed, tension structures shaped like clamshells-to support its aviation maintenance activities.

US forces used various expedient shelter systems for troop billeting and operations in the theater, including festival tents, clamshell buildings, sprung structures, and K-Span. Festival tents, purchased from Germany where they were used on holidays for temporary beer halls, were sometimes difficult to erect in the desert. The lightweight, compact clamshell buildings were assembled rapidly on site. They could be erected in four days by an untrained platoon. The sprung structures, in which a tension fabric skin covered a metal frame, required scaffolding and a crane to erect.

The Air Force had organic Prime BEEF teams for its forces and the Navy provided organic Seabee battalions to support the Marine Expeditionary Force. But the Army had no troop construction capability in the theater during the initial phase of Desert Shield. As a result, combat engineer battalions were diverted from operational and training missions. The Army needed to identify organic construction assets in its engineer force for deliberate support of the contingency.

Originally conceived as a rear area rest and refit facility, FP is a readily deployable, containerized and pre-packed base camp developed by the Army between 1992-1994. Using flexible configurations of tents and containerized systems, each FP module -- also called a 'base-camp-in-a-box' -- can support about 550 people and offers quality of life amenities not normally found in the field.

Among the wide variety of containerized and rapidly deployable systems that make up FP are air-conditioned tents, hot showers, a full-service kitchen, on-site laundry service and flushing toilets. Other amenities include recreation such as basketball, table tennis and satellite television. Each module also offers a chapel and a small medical facility for use by the visiting unit's staff.

FP is managed by Product Manager-Force Sustainment Systems (PM-FSS) located at the U.S. Army Soldier Systems Center in Natick, Mass. PM-FSS is an element of Project Manager-Force Projection within the Program Executive Office for Combat Support and Combat Service Support (PEO-CS&CSS).

Force Provider Development

Operation Desert Shield/Desert Storm reinforced what many soldiers had suspected for years: the Air Force was head and shoulders above the Army when it came to comfortable field facilities. In July 1991, after Desert Storm, Army Chief of Staff General Gordon R. Sullivan set out to change all that. The Army's Force Provider concept was born a short time later.

The challenge to 'improve the quality of life for soldiers' went to the commanders of the US Army Training and Doctrine Command (TRADOC) and the US Army Materiel Command (AMC). In November 1991, the project was assigned to TRADOC's US Army Quartermaster Center and School (USAQMC&S) at Fort Lee, VA, and to AMC's Natick Research, Development and Engineering Center in Massachusetts.

TRADOC and USAQMC&S defined the organization and equipment requirements for Force Provider to support diverse missions. Force Provider is containerized for easy air, land and sea transport. Also, the containerized system is modular for operating in a variety of tactical environments.

TRADOC and AMC tailored the Air Force's Bare Base concept to meet Army needs. The resulting Force Provider design was engineered in less than two years by selecting from the best combat service support equipment available within the Department of Defense.

Force Provider was operationally tested on Nijmegen Drop Zone at Fort Bragg, NC, by the Operational Test and Evaluation Command. This test ensured system design suitability, verified the adequacy of the Quartermaster Force Provider company's staffing levels and provided a training opportunity for the first operators of Force Provider.

During the test, soldiers from a test Force Provider company operated the Force Provider module in a scenario simulating actual use. Soldiers from the XVIII Airborne Corps rotated through the Force Provider module for three-day periods. A total of 1,650 soldiers had the opportunity to test and take advantage of all that Force Provider had to offer. The Force Provider team used test results to finalize doctrine and the table of organization and equipment, and to support a full-scale production decision.

Force Provider Capabilities

The Force Provider is a transportable base camp system that provides housing and operation space for a variety of military missions ranging from support of a small military outpost to a fully operational, forward deployed base camps and airbases. With the standardization of the Military, Force Provide can be combined with USAF's Harvest Falcon and/or Harvest Eagles for joint base camp operations.

Force Providers are a combination of military and commercial products that provide climate-controlled billeting, quality dining facilities, hygiene services and morale, welfare and recreation facilities for deployed troops. Force Provider modules vary in size to accommodate 550 to 3,300 people each. A single Force Provider module for 550 personnel is packaged in about 103 TRICONs, five 20-foot ISO containers, 27 trailer-mounted generators, and assorted other self-storing items. The basic building block is the Tent Expendable Modular Personnel (TEMPER), each of which has an environmental control unit.

Force Provider systems come complete with water and fuel storage, power generation and distribution, and wastewater collection systems. They are containerized and preconfigured for easy movement by land, air and sea.

A single Force Provider site requires five to ten acres of land. Site preparation takes three to four days, and an entire camp can be fully operational in about 14 days using 50 personnel.

Force Provider uses the modern air-conditioned and heated Army Tents Extendable, Modular, Personal (TEMPERs) as its basic building block. TEMPERs house Air Force showers and latrines, serve as billets and kitchen and dining facilities and also accommodate morale, welfare and recreation (MWR) centers. The Army's new 60-kilowatt tactical quiet generators or 750-kilowatt generators from an Army prime power battalion supply Force Provider with electrical power.

Force Provider's mission is to give frontline soldiers a brief respite from the rigors of duty. The modules can work independently or with one another. Each module provides the following:

- Climate-controlled billeting activities.

- Food service.

- Shower and latrine facilities.

- Laundry service.

- Facilities for MWR activities.

Also, additions of a small post exchange (PX) capability, automatic teller machines (ATMs) through satellite uplinks, telephones for soldier use, and expanded recreational facilities are being considered.

A brigade-sized cluster would require about 66,000 gallons of water each day and about 10,000 gallons of fuel daily. The Force Provider site itself will cover approximately 35 acres, including 10 acres for liquid and solid waste disposal.

The Force Provider unit will depend on the following:

- Appropriate elements of the corps or theater Army for finance, legal, personnel and administrative services, additional security, and supplemental transportation support.

- A heavy Combat Engineer battalion for site preparation.

- An Engineer fire fighting team and fire truck for fire fighting.

- A utilities team for utilities operation.

- A Quartermaster supply company for potable water supply.

- A resident unit ministry team for religious support to attached unit.

- An Engineer prime power battalion for power generation support.

When fully operational, 1 brigade-sized module can serve up to 1,500 meals each day from 8 containerized kitchens, including refrigeration trucks or reefers and dining tents; provide personal hygiene facilities for 280 soldiers from 14 latrines, each consisting of 12 toilets, 4 urinals and 4 sinks; provide 3 showers a week for each soldier from 6 shower units, with 9 shower heads in each unit; provide billeting in 275 TEMPERs capable of billeting 12 soldiers, complete with cots, liners, floors and lighting; provide laundry services to 15 pounds of each soldier's clothing each week by 6 laundries; and provide 20 gallons of water a day for each soldier through the use of four 20,000-gallon collapsible water tanks and three 3,000-gallon reverse osmosis water purification units.

Force Provider Employment

A Force Provider module or modules would be assigned to a headquarters and headquarters detachment in a theater army area command or a corps support command (COSCOM), a supply and services battalion, or a headquarters and headquarters company in a corps support group. However, the Army plans to locate a Force Provider module or modules as far forward as the division support area. The supported commander will decide the location.As of 1997 the Army planned to acquire 36 Force Provider modules through fiscal year 2002; the first two were delivered in December 1996. However, well before those first modules were delivered, the Army's leaders recognized the need for an interim Force Provider-type capability to support contingency missions. So Headquarters, Department of the Army (HQDA), directed that twelve 550-soldier interim support package (ISP) modules be assembled from the Army inventory. The ISP modules (6 in ISP 1 and 6 in ISP 2, with each ISP capable of supporting a brigade-sized force of 3,300 soldiers) were assembled and packaged at Sierra Army Depot, California, between March 1994 and May 1995. ISP 1 has been deployed to Army War Reserve-3 on the prepositioning ship Gopher State since the summer of 1994, while ISP 2 was deployed to Tuzla for Operation Joint Endeavor.

The ISP modules can be available within 30 to 60 days by surface transportation. Each Force Provider module is stored and shipped in 109 TRICON and 5 standard ISO containers. A module is transportable by all modes, including C-130 aircraft (54 sorties), C-141 (24 sorties), C-17 (12 sorties) and C-5 (9 sorties). The Army inventory initially consisted of 12 interim support package (ISP) modules (near-Force Provider configuration) and 1 Force Provider test module. Six ISP modules are deployed on the prepositioned ship Gopher State. Six modules are stored at Sierra Army Depot. One Force Provider test module is deployed to Guantanamo Bay, Cuba.

The Army has two Force Provider companies in the Active Component. One is assigned to the 1st COSCOM's 507th Support Group (Corps), 530th Supply and Services Battalion at Fort Bragg, NC. The other is assigned to the 13th COSCOM at Fort Hood, TX.

Each Force Provider company consists of six platoons. Each platoon, when augmented, can operate one 550-soldier module. Each module can support 550 soldiers separately or a brigade-sized force of 3,300 soldiers if all six modules are combined.

Also, the Army plans to have four Force Provider companies assigned to the US Army Reserve to bring the total number of Force Provider companies to six, enough to support 19,800 soldiers or thirty-six 550-soldier modules.

In addition to Force Provider's basic mission of giving a brief respite to frontline soldiers, the modules can be used during initial theater reception if deployed early. The modules can also provide a rest stop as soldiers move forward in the theater, collocating with other activities such as maintenance units or Refuel on the Move points. Following the theater's mission, Force Provider could be used in the reverse, as a redeployment staging facility. Finally, it could also support a myriad of other missions, including soldier rest and refit, convoy support, and intermediate staging base operations. Force Provider also is envisioned as a system to support noncombatant evacuation, humanitarian aid, and disaster relief missions such as Hurricane Andrew.

In August 1993, the Department of the Army (DA) approved making the commander of each Force Provider company a major. Although the company requires 445 personnel, only 44 Army soldiers are authorized. The remainder would be filled by Department of the Army civilians, contractor personnel, local nationals and third country nationals.

The main revisions in the Force Provider structure will be in the platoons and the support, services and engineer sections. The proposed sections will be embedded in the Force Provider structure, instead of as augmentation pieces as required in the current structure. The redesigned Force Provider Company will have Force Provider platoons, which will consist of a Force Provider light platoon, a medium platoon and a heavy platoon.

The Force Provider light platoon, supporting up to 550 Soldiers, will be designated as a rapid deployer for operations of 15 to 90 days. The light platoon will provide billeting, showers, laundry, latrine services and limited dining operations.

The Force Provider medium platoon will support operations for 90 days to 18 months or more. The medium platoon will support 550 to 3,000 Soldiers with billeting, showers, latrine, laundry, dining facilities and MWR services. The Force Provider heavy platoon will support operations of 18 months or more. The heavy platoon primarily will support brigade-sized elements.

The heavy platoon will offer the same services as the medium platoon, except that most Force Provider services will be in semipermanent structures with a focus on complete base camp operations. The type of semipermanent structure had not been decided as of 2003. Semipermanent structures are being considered because Force Provider TEMPER tents will be exposed to an excessive amount of wear and tear during 18 months or more of operations.

One obstacle to proper employment of Force Provider is the lack of education about this support system's capabilities. Education will allow commanders to understand the magnitude of the service operation.

Force Provider Deployments

Land Air Sea 54 User Manual Download

Force Providers have made high-quality living conditions possible in Haiti, Cuba, Bosnia, Guatemala, Honduras and various locations in Kuwait in support of operations Enduring Freedom and Iraqi Freedom. Five modules were deployed and set up near Kandahar in June 2002, housing soldiers engaged directly in the continuing combat operations inside Afghanistan.

In October 2002, the Army began to deploy, set up and operate overseas-based FP modules in support of Operation Enduring Freedom. In November, seven FP modules were in transit to the theater of operations. By the end of December 2002, these systems were established and provided an early entry capability that served as the first forward base camp facilities to directly support air and ground combat operations inside Afghanistan.

FP modules were employed at two sites. In Uzbekistan, they were operated entirely by the Army and provided support to SOCOM, Army and coalition forces. In Kyrgyzstan, Air Force personnel set up and operated the base camp strictly for airfield operations.

At both sites, Air Force Harvest Eagle/Falcon base camps, similar to FP, were collocated with the FP equipment, proving that FP offers a joint capability.

In Uzbekistan, Force Provider modules at Camp Stronghold Freedom were operated and maintained by two US Army Reserve (USAR) companies: the 542d Force Provider Company, Erie, PA, and the 802d Force Provider Company, Columbus, GA. The 542d and 802d, as Force Provider Type B companies, operated and maintained four Force Provider modules and three Air Force Harvest Eagle modules with 77 Soldiers. The Camp Stronghold Freedom base camp, on the average, was supporting about 3,500 Soldiers on a daily basis.

By February 2003 six tent cities in Kuwait had space for 15,500 soldiers. Camp sizes in Kuwait ranged from 500 to 6,500 personnel. Dining facilities increased their capacity to feed up to 10,000 per day with projected increases to reach 20,000 per day. U.S. Army Materiel Command's Program Management Office for the Logistic Civil Augmentation Program, know as LOGCAP, arrived in Kuwait in September 2002. LOGCAP helped develop plans to construct six Force Provider modules to provide bedding for nearly 3,500 personnel. By February 2003 the number had more than quadrupled for soldiers housed and it continued to grow. Both Force Provider and Festival Tent communities were built under the LOGCAP contract.

| Join the GlobalSecurity.org mailing list |

DCS: A-10C II Tank Killer adds new weapons such as; the Advanced Precision Kill Weapons System (APKWS), AGM-65L laser-Maverick, and GBU-54 laser-guided JDAM. A completely remodelled cockpit with options for factory-fresh and weathered textures. The “Scorpion” system used to train the 355th Wing cadets and the updated external model now set the bar for our future releases.

We have updated the preset key commands for HOTAS hardware to make new users feel more comfortable learning this in-depth system. The fully interactive Forward Air Controller (FAC) will also help you find and engage enemy targets, cooperative target engagement has been taken to a new level.

With the improved ability to command ground forces, the vast number of land, air and sea units as well as feature-rich cooperative missions and head-to-head multiplayer; We are proud to say this is the most realistic model ever done for PC simulation.

Pricing Policy

DCS: A-10C II Tank Killer is available now for $79.99. If you own DCS: A-10C Warthog, you can upgrade to DCS: A-10C II Tank Killer for only $9.99 until the 31st of October 2020. After that, the upgrade will cost $19.99.

The upgrade option and module are both available on Steam and Eshop now.A new addition to the renowned A-10C is the Helmet Mounted Cueing System (HMCS). It provides excellent situational awareness and the ability to cue weapons and sensors by just looking at the target and setting a designation. Please note that this is not the same helmet implementation as for the Viper and Hornet systems; it is in many ways far superior.

Watch the last video in the DCS: A-10C II Tank Killer Preview Series:

Land Air Sea 54 User Manual Pdf

DCS: A-10C II Tank Killer | Helmet Mounted Cueing System (HMCS).

Land Air Sea 54 User Manual 2

Learn and fly whilst using the updated Tank Killer Manual.